How RPA Solved Material Master Challenges for a Leading E&P

AG optimised material master creation processes for a Global Energy Operator by replacing error-prone, manual workflows with an advanced Robotic Process Automation (RPA) solution.

A leading independent exploration and production company recognised the need to overhaul its material master creation process to stay competitive and agile in a demanding market. Recognising the immense potential for transformation, the company partnered with AG to implement a cutting-edge automated solution for Material Master creation.

Speak to an SAP expert today

Navigating Complexity: A Strategic Approach to Material Master Management

In the dynamic landscape of global oil and gas exploration and production, optimising supply chain processes is crucial for maintaining a competitive edge. A leading independent European exploration and production company with operations spanning across Europe, North Africa, and Asia Pacific, recognised the need to revolutionise its material master creation process to enhance operational efficiency and adapt to evolving market demands.

Facing challenges with manual data entry, errors, and governance, the company sought to enhance operational efficiency, the company partnered with AG to transform its material master creation process.

AG's implementation of an automated, state-of-the-art platform addressed these issues, driving significant improvements in data accuracy and process efficiency. This strategic initiative streamlines operation, aligns with the company's vision of becoming a leading international independent E&P company, and supports their pursuit of sustainable energy leadership, positioning them for continued success in the evolving energy landscape.

Read the full story!

Download Case Study

Transforming Material Master Data Governance with

AG's Intelligent Automation

Maintains Clean, Accurate database

Enhances document creation with accurate, duplicate-free data while seamlessly integrating workflows with existing SAP rules.

Brings Transparency & Visibility

Delivers a full, comprehensive material master process report across multiple systems, ensuring zero ambiguity.

Enables End-to-End Compliance

Ensures consistent, rule-based real-time reporting, with end-to-end compliance for all SAP material master changes across key business operations.

Accelerating digital transformation requires a structured, efficient approach to data management. The SAP Material Master creation process is a key foundation for enterprise-grade ERP operations to overcome manual data entry and labour-intensive, time-consuming, and error-prone processes. Poor coordination in batch creation can lead to discrepancies in orders, shipments, and inventory management—impacting business efficiency.

AG’s intelligent automation technology eliminates these inefficiencies by enabling seamless, error-free material master data creation.

Rahul Kumar, RPA Technical Solution Lead, AG

Our fully automated bot integrates data from multiple stakeholders, ensuring a streamlined, standardised, and compliant workflow. As enterprise data volumes grow, our automation solutions optimise and enhance company-wide material master governance—reducing manual intervention, improving data accuracy, and accelerating critical decision-making. With built-in duplicate checks at every stage, AG’s automation solution successfully prevents redundant entries. By automating material master data governance, organisations can achieve:

- Efficient, Real-Time Data Processing

- Seamless Integration with SAP Business Rules

- Improved Accuracy and Compliance

- Significant Cost and Time Savings

An Overview

In the fast-evolving landscape of global energy exploration and production, achieving efficiency and precision in supply chain management is paramount. A leading independent exploration and production company recognised the need to overhaul its material master creation process to stay competitive and agile in a demanding market. This case study explores the company's transformative journey, partnering with AG to implement a cutting-edge automated solution for Material Master creation.

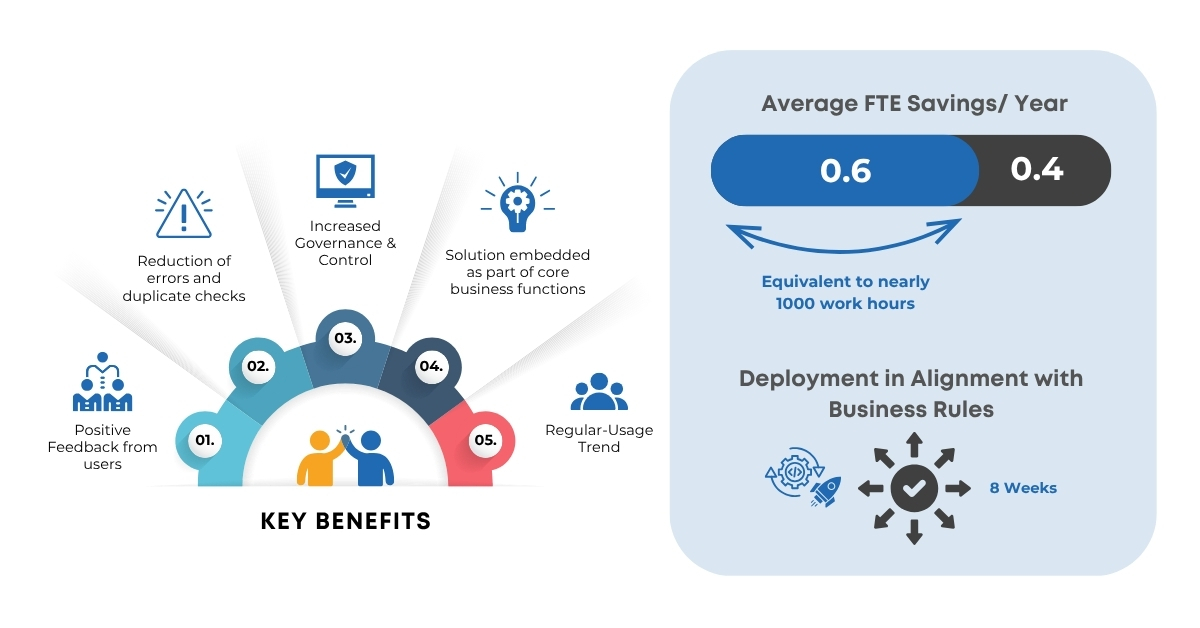

We were up and running in 8 weeks thanks to AG. We've seen a 70% increase in material master processing and a noticeable drop in manual effort and duplicates, bringing real efficiency to our procurement operations.

Chief Procurement Officer

The Challenges

The company’s procurement team faced a multitude of challenges in their day-to-day operations:

Manual Data Entry Burden

Stakeholder Complexity

Data Quality Issues

Complex Business Rules

Inefficient Workflows

Lack of Standardisation

Manual Data Entry Burden

The existing process heavily relied on MS Excel for creating material masters, requiring significant manual input and increasing the risk of human error.

Stakeholder Complexity

Multiple business parties were involved in the end-to-end process, leading to communication gaps and inconsistencies.

Data Quality Issues

The manual process resulted in frequent data entry mistakes, duplicate entries, and inconsistencies within the SAP system.

Complex Business Rules

Intricate processes involving various departments increased the likelihood of missed steps and procedural oversights.

Inefficient Workflows

The manual nature of the process led to frequent rework, slowing down operations and frustrating team members.

Lack of Standardisation

Inconsistent approaches to material master creation hindered data governance efforts and made reporting challenging.

These challenges not only impacted the efficiency of the company's procurement operations but also had ripple effects throughout the supply chain, affecting project timelines and budget allocations.

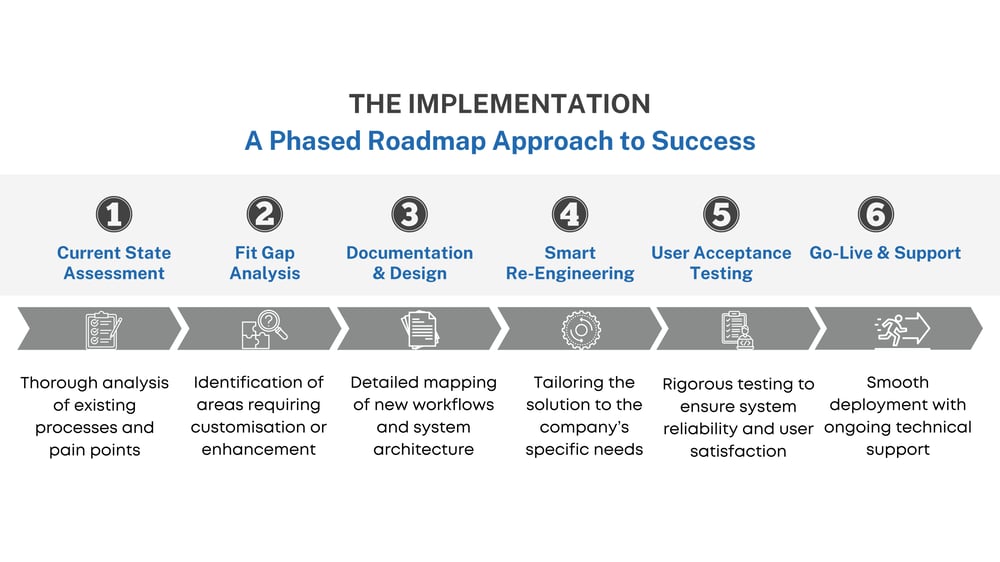

The Solution: A Phased Roadmap to Success

To address the inefficiencies in manual material master creation, AG deployed a phased roadmap to success with the SAP Material Master Data automation solution. This streamlined processing minimised errors and improved data accuracy and governance, ensuring a seamless transition and maximising system benefits.

AG’s Automation Solution resulted in the following positive impact on their overall business performance.

This automation tool is regularly used by the business to efficiently manage and automate:

- 83 Plants

- 82 Storage Locations

- 3 Valuation Types

- Price Updates

Identified inefficiencies within the SAP Material Master, including duplicate records, manual data entry points, and compliance issues.

Conducted a gap analysis to evaluate SAP Build capabilities and determine where automation and enhancements were needed.

Designed an automation blueprint outlining key process improvements and integration points within SAP.

Deployed SAP Build automation to digitise material master updates, eliminate manual inputs, and improve data accuracy.

Tested automated processes for performance, security compliance, and end-user experience to ensure stability.

Deployed the solution using structured change management, with continuous monitoring and iterative optimisation.

Throughout the implementation, AG worked closely with the company’s IT department to ensure seamless integration with existing systems and adherence to corporate security and governance protocols.

Key Improvements

Contact our SAP experts to fully automate your material master data governance and significantly reduce manual effort.

Contact us today...